Contact us

Learn more about "AIS Conveyor 2.0"

And about the possibility of its implementation in your factory

And about the possibility of its implementation in your factory

We are optimizing all production processes with the help of Industry 4.0 technologies

+91 99308 88110

sales@shamvikglass.com

Increase the productivity of your factory by 10%

Industry 1.0:

big data and artificial intelligence in the service of efficient production

Industry 4.0:

Industry 2.0:

Industry 3.0:

mechanization, steam-engine

electrification, assembly line production

automation and robotics

New patterns already exist!

Everything is under control

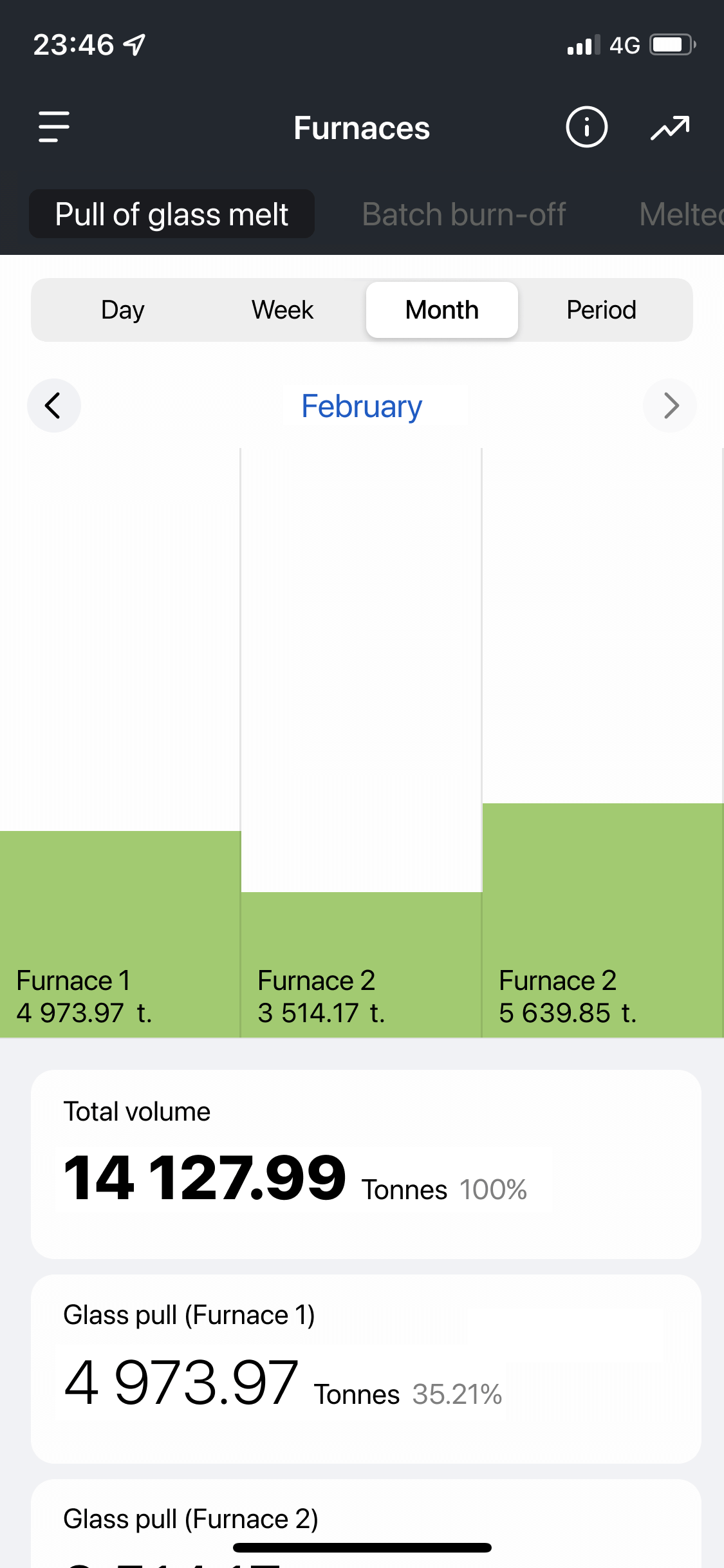

“AIS Conveyor 2.0” allows to control all manufacturing processes in real time, build up the balance of raw materials and shorten the “reaction time”

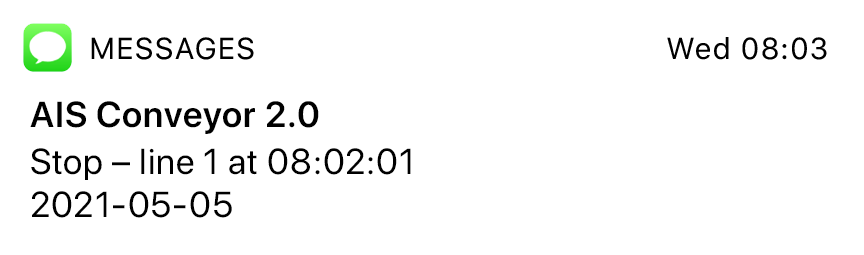

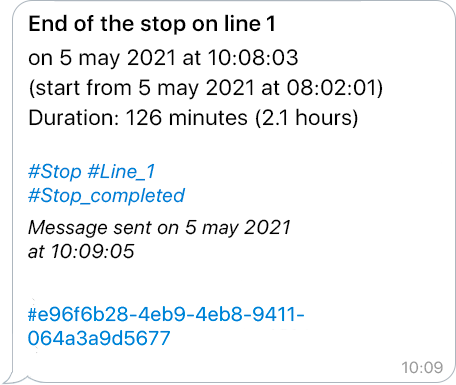

Always stay informed

If something happens in the plant “AIS Conveyor 2.0” will send you a message via the phone or Telegram

Burn-off in the furnace

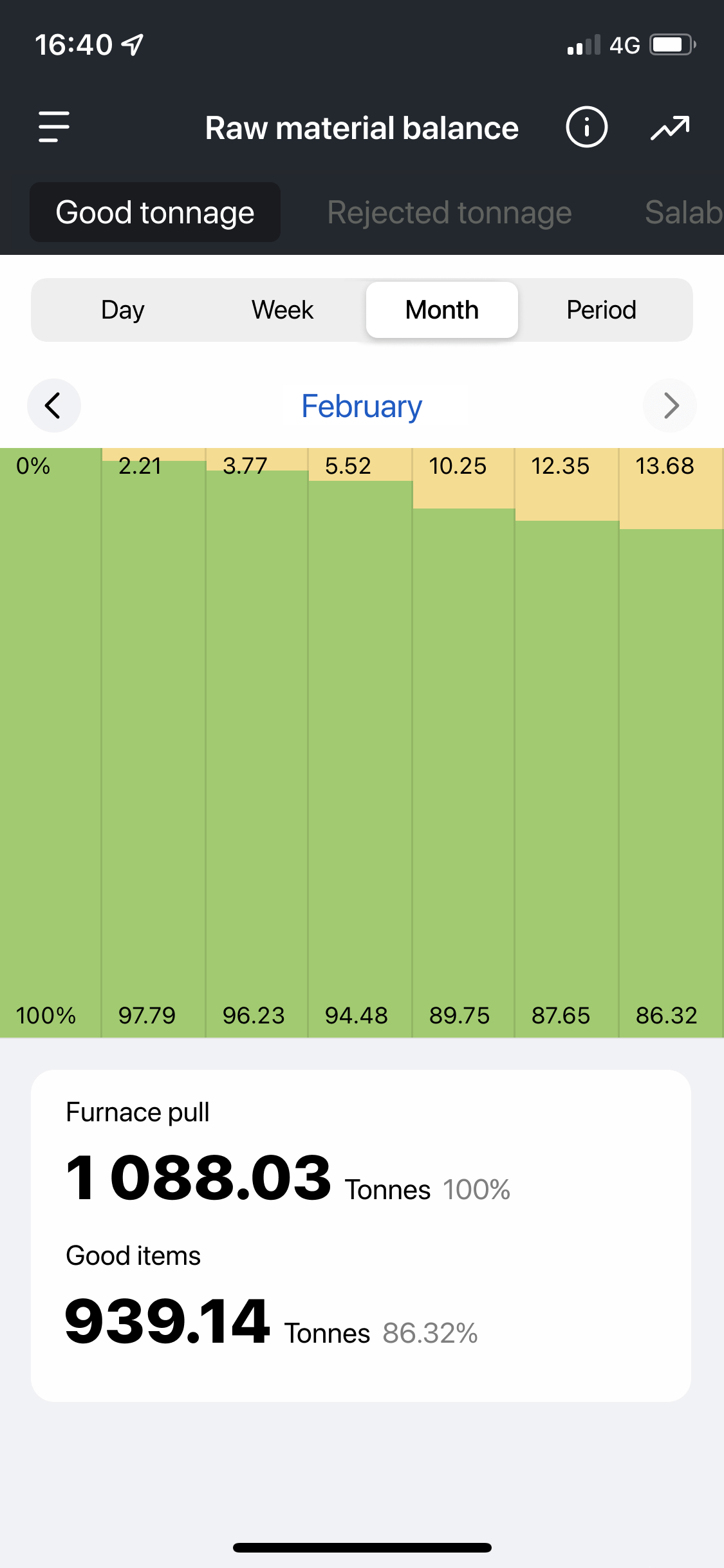

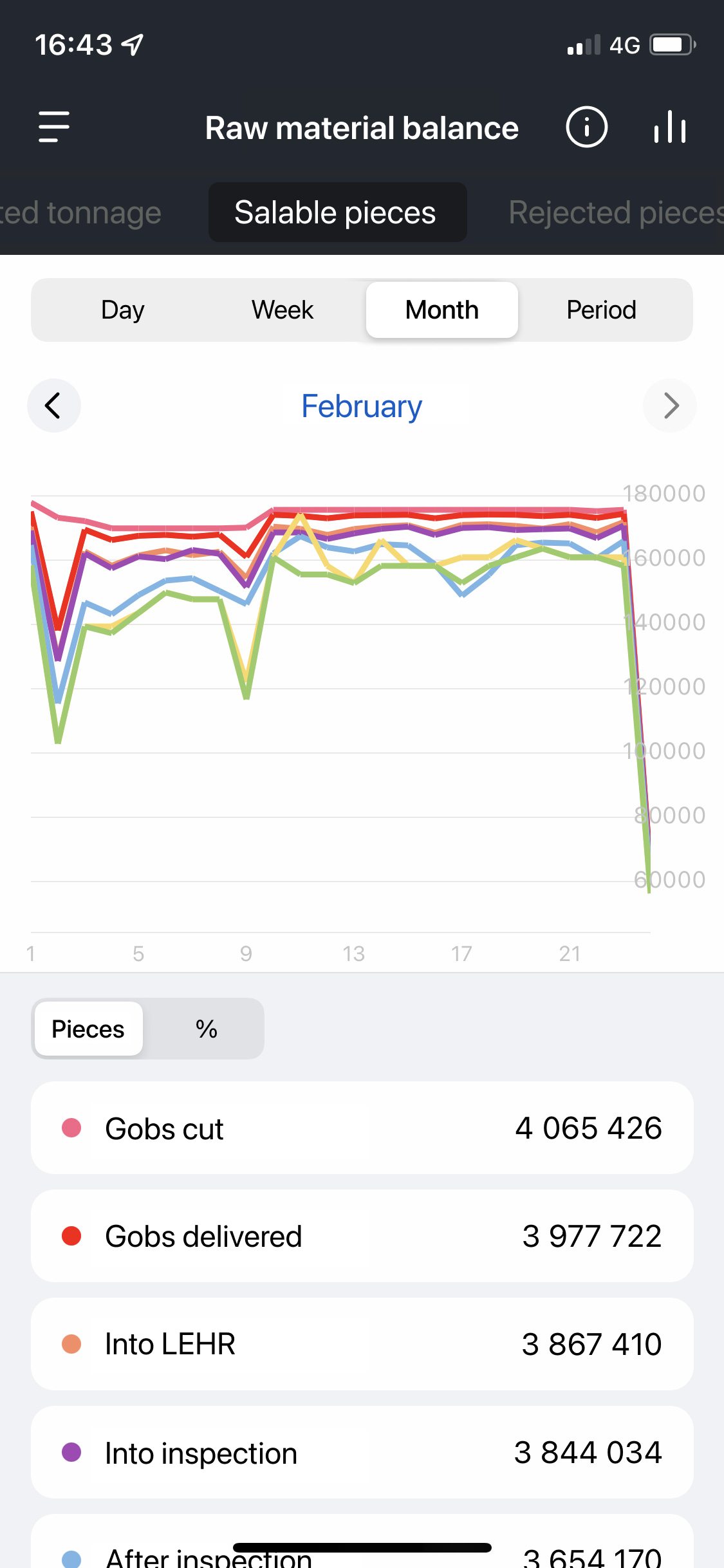

Raw material balance

Counting and recording of the pallets by identifiers

Moulds operating time

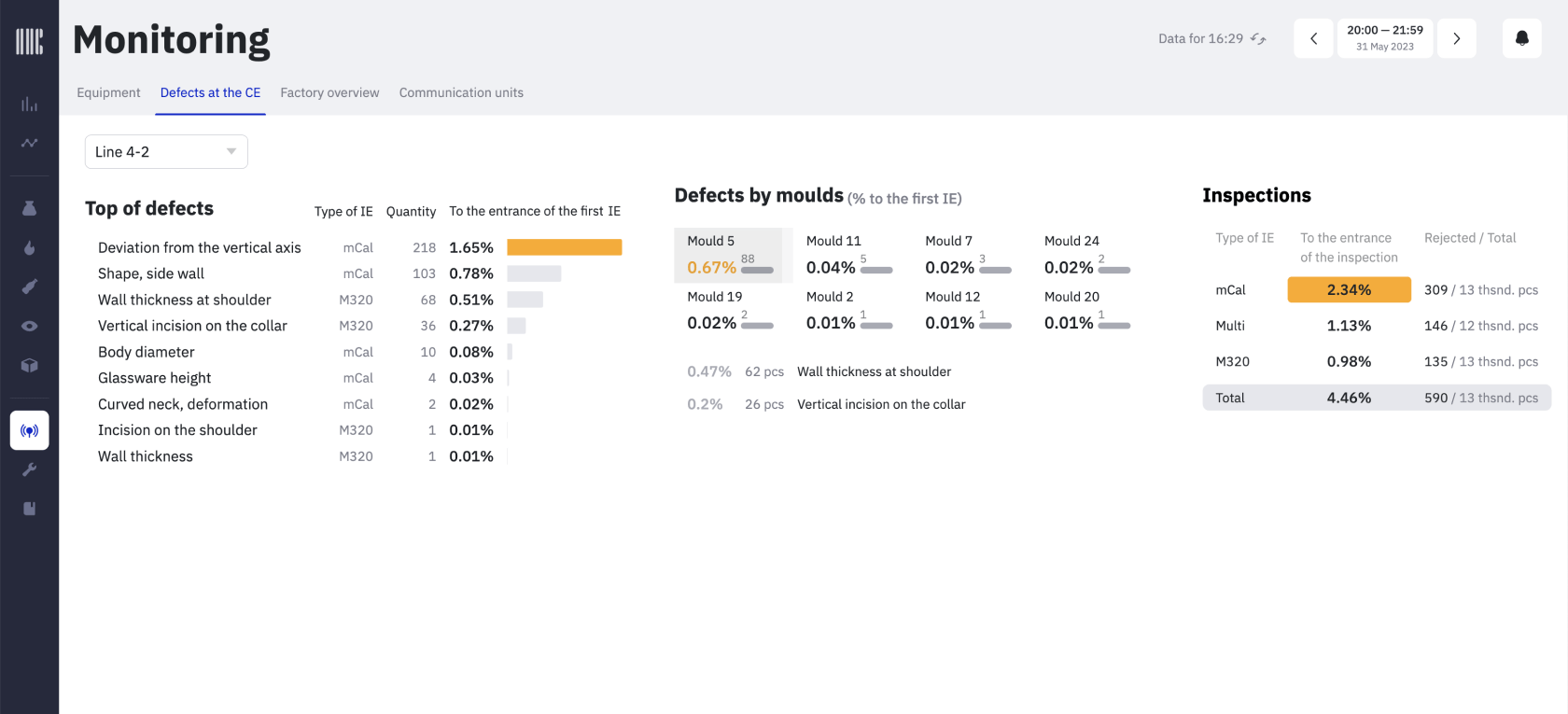

Defects and rejects

Gob weight

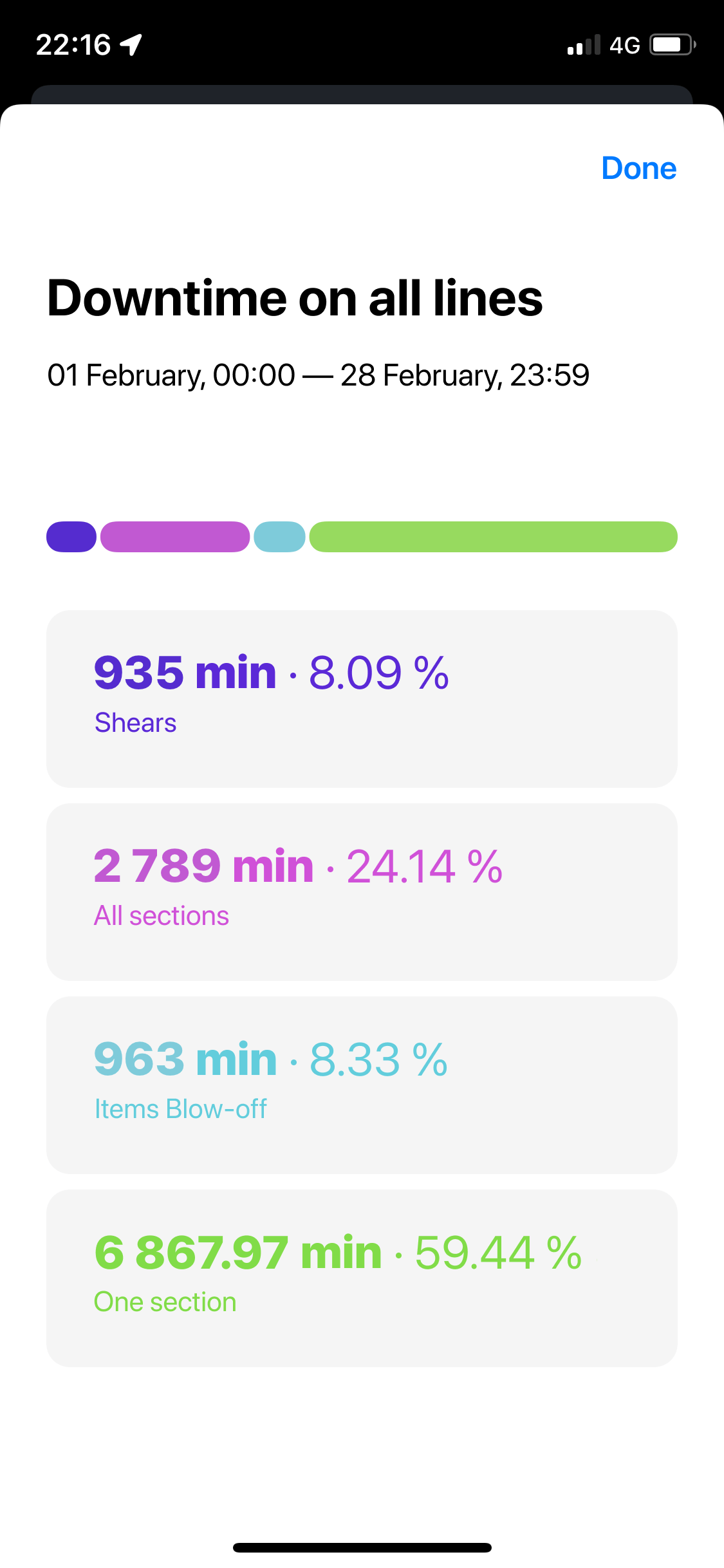

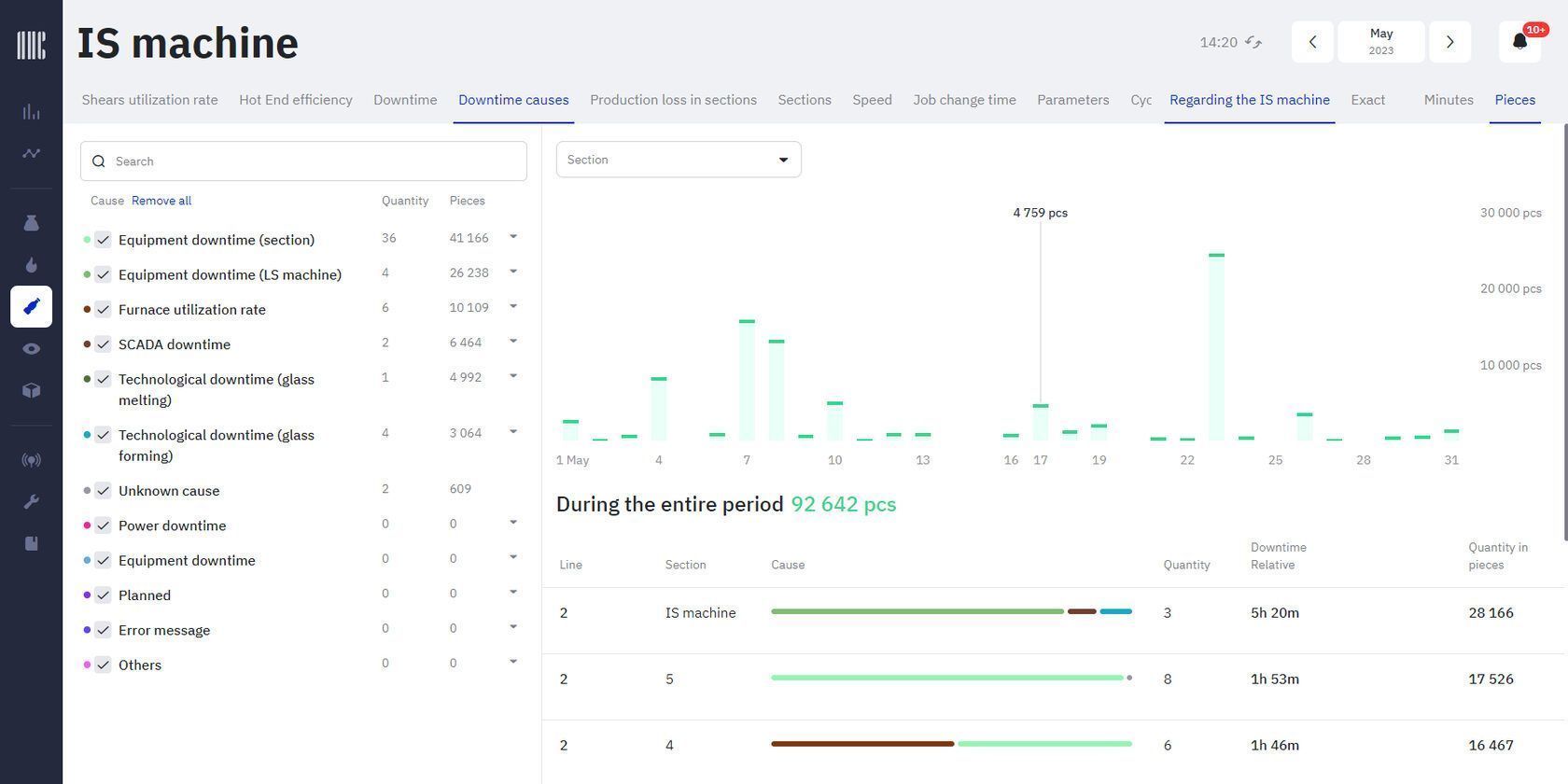

IS machine downtime analytic

Speed of cuts

The whole plant in the palm of your hand

Efficiency and PTM

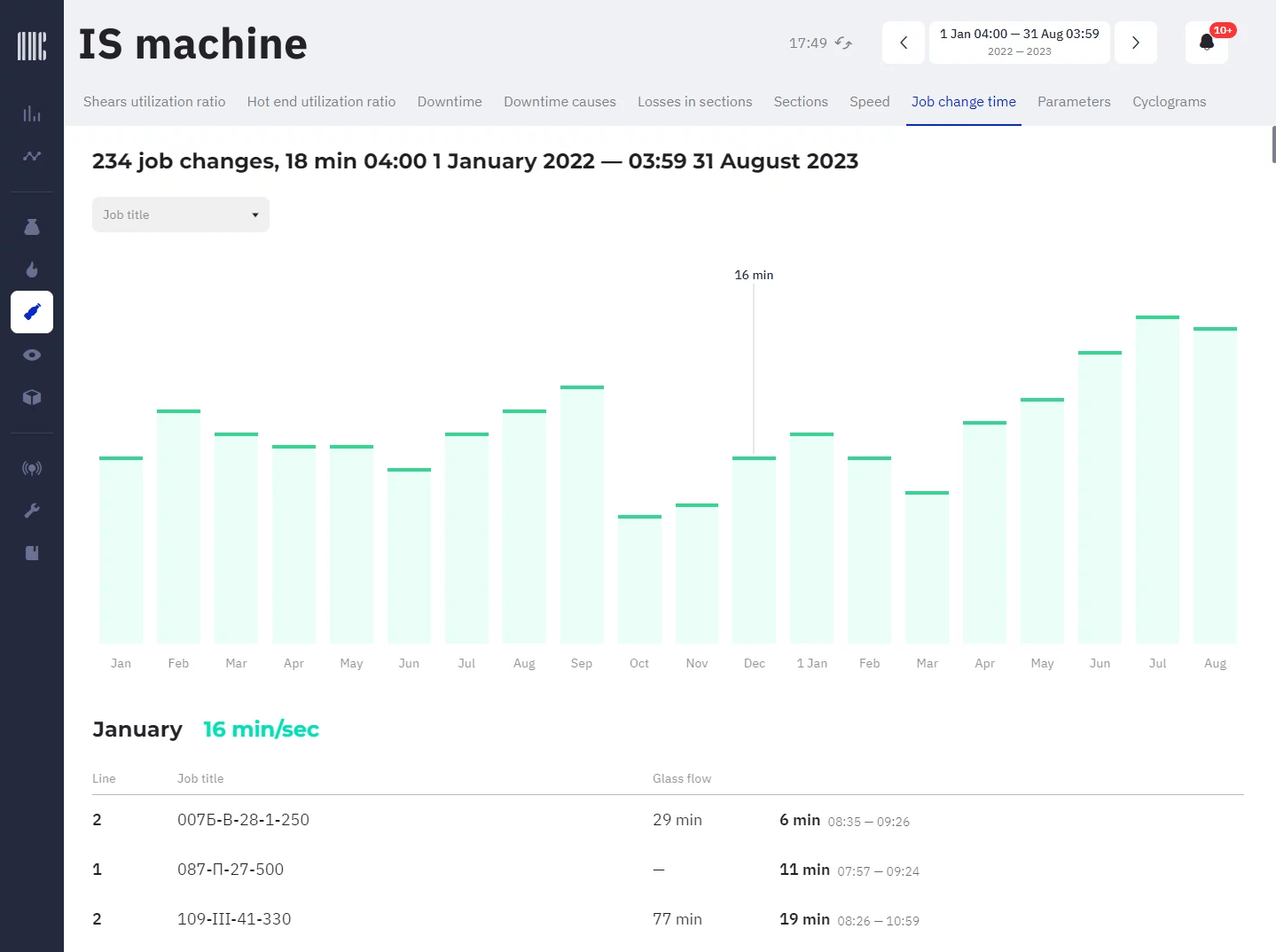

Using objective data, set new KPIs with appropriate motivation for employees performing work on reconfiguring IS machine from one product range to another.

Real growth of the profit

“AIS Conveyor 2.0” increases the productiveness by increasing the time of effective work of IS machines and by maximizing the utilization of available sections. It also increases pack-to-melt ratio by decreasing the number of rejections due to shortening of “reaction time”

Create a system of objective control over the time of job change team work (T1) and over the time of reaching the planned glass melt using rate after the job change (T2).

Time T1 and T2

Objective control and KPI analytics system

The system automatically collects, combines and analyzes data. The truth is formed once and forever — the data cannot be changed. This approach creates an objective idea about the efficiency of the production process organization. This is a transparent and effective tool for enterprise management and workers motivation.

Analytics by types and reasons of IS machine downtime

Time of effective operation of the IS machine

Losses control in all areas

Planned and actual time for job change and entering the planned production speed mode (T1 and T2)

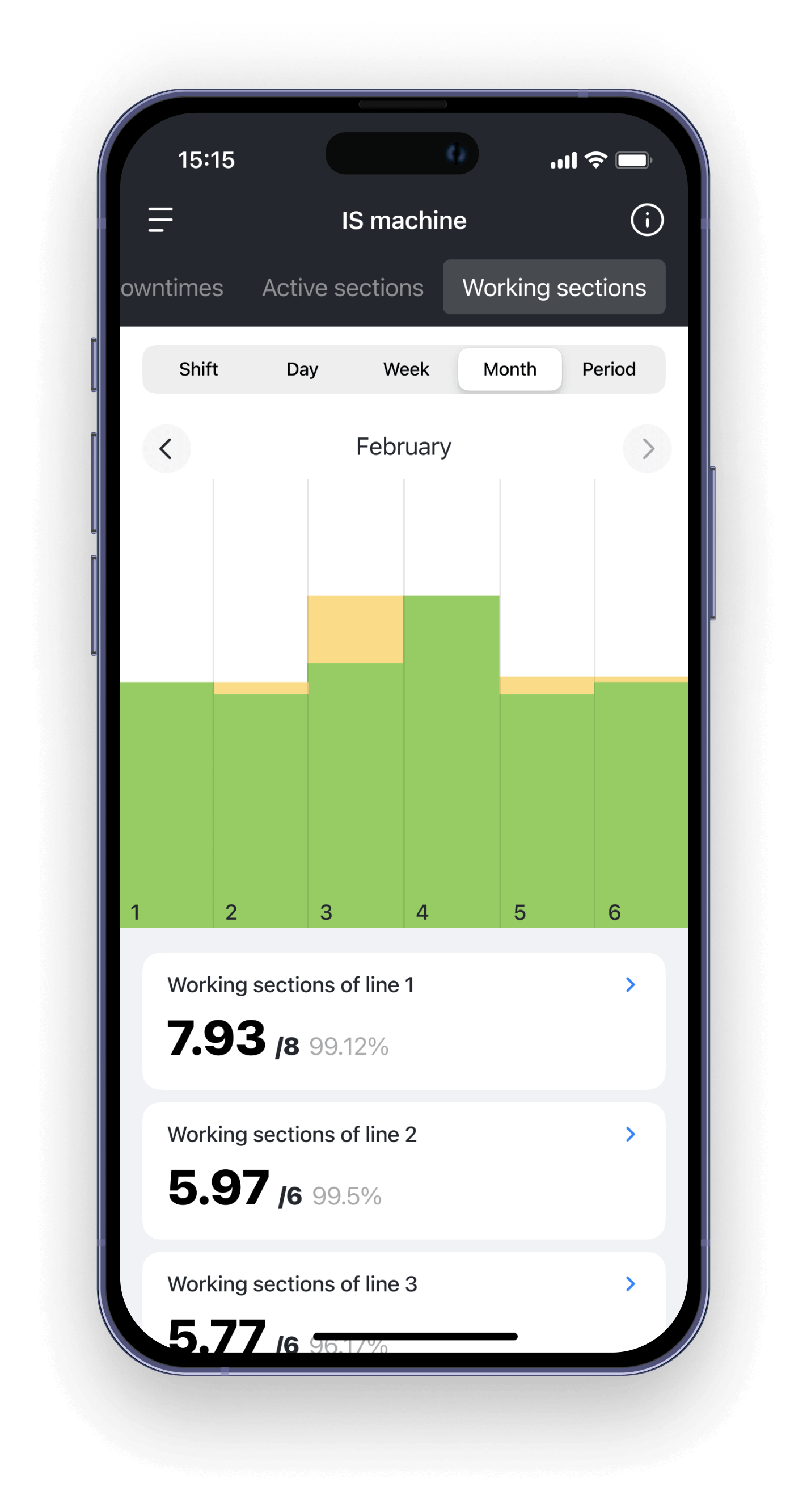

Utilization rate of shears and sections

Yield rates of good and used glass melt

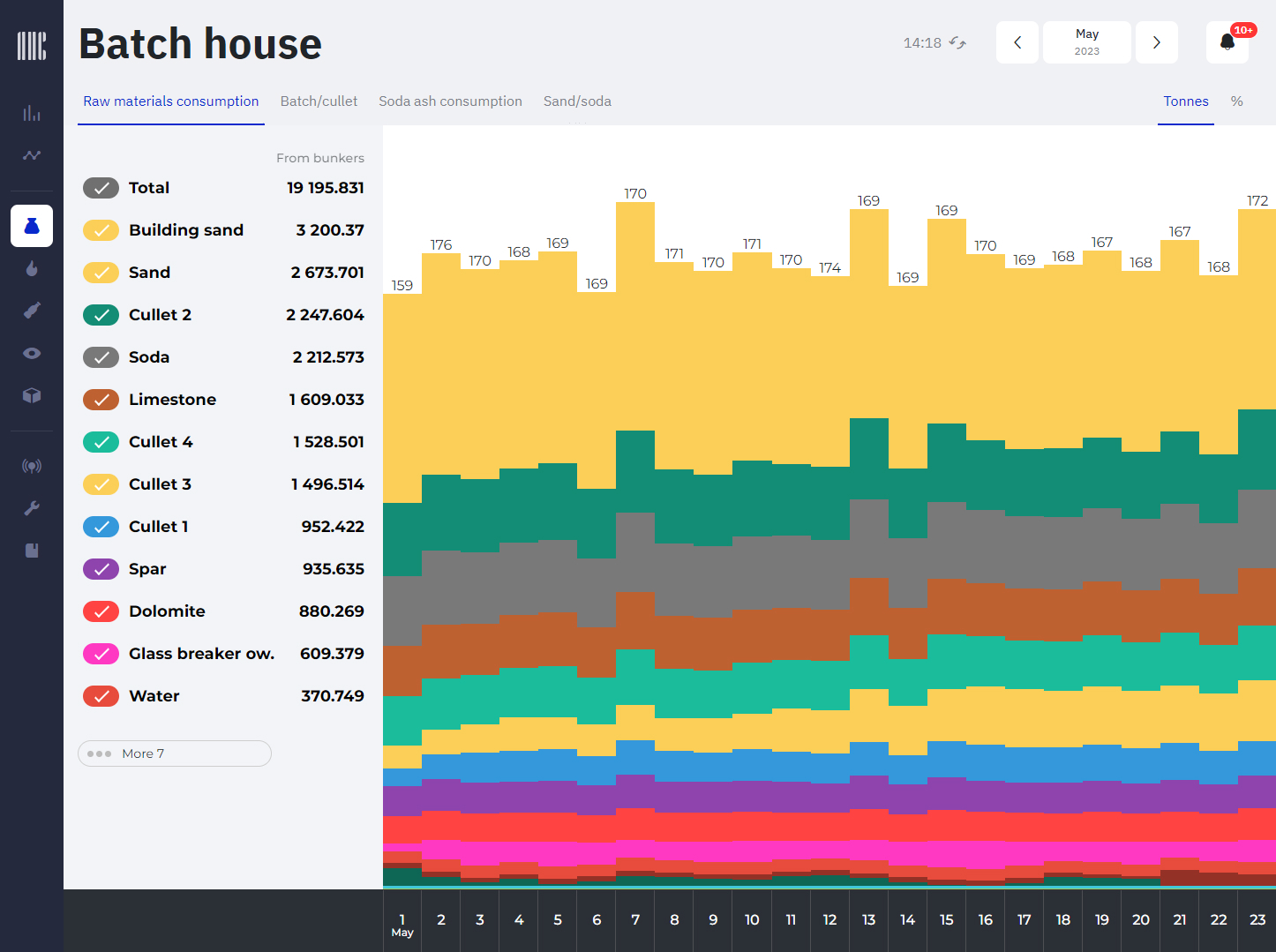

Raw materials consumption

The Balance of raw materials is controlled in the form of closed cycle: from the loading of raw materials in a batch house to the shipment of finished products. Data is read directly from the process control system and is synchronized with accounting and recording systems, which eliminates the human factor:

calculation of the percentage of pure charge burn-off

monitoring the consumption of raw materials in the context of ingredients, calculating the change in the remains of own cullet

waste control in all areas

PTM growth

The system reduces "reaction" time by connecting the hot and cold sections of the conveyor by placing a monitor in the operator's rooms. These monitors visualize defects detected by inspection equipment, as well as use online notifications when the critical threshold of defects in any form is exceeded, at the same time measuring the time spent on eliminating the causes of defects.

+4%

The list of defects associated with each product range and mold number is maintained for each inspection machine.

Productivity boost

20%+

The time of effective operation of the IS machine is growing — downtime is reduced with the help of online monitoring and analysis of the types and causes of downtime.

Profit growth after the implementation of the solution

Proven economic effect from using the system

+10%

Increase overall plant productivity through smart scheduling using line-by-line productivity statistics for each range of product. Items are distributed to those lines where they are produced with maximum cutting speed and efficiency (PTM)

Big Data of your factory

During which shifts is the line performance at a higher level?

What is the dynamics of production indicators: a year ago, a month ago, yesterday and today?

What, when and with which speed was produced on the lines?

How much time does it take to do the job change and enter the planned efficiency after the job change?

At what settings of the IS machine the performance of the lines was the best and the worst?

Everything about production in real time and in retrospect!

On which lines each of items is produced with the maximum speed and efficiency?

We have created an APP for smart-phone to help you assign statuses to finished products. The employee scans the pallet code and selects the status:

At the stock

Shipped

Blocked

Rejected

Dissassambeled or any other status which is used in your factory

We adjust the application to your needs and will connect it to any number of employees.

Accounting of pallets according to quality standards

Machine vision and artificial intelligence recognize and read each pallet as well as check the number of rows. We install cameras in the area of palletizers and shrinking machines. Each pallet will be counted.

Connect equipment that will benefit you

Not a public offer

Prices are inclusive of

Hardware

Software

Installation

Software

Installation

Glass forming — Machines

Hot End and Molds

6 850 000 ₹

per line

Packaging, Warehouse, Pallets

Pallets

2 400 000 ₹

per line

Quality control, Inspection machines, Defects

Cold End

2 850 000 ₹

per line

Batch house

Batch house

1 550 000 ₹

per furnace

Why “AIS Conveyor 2.0”?

Growth of efficiency due to internal resources

Complex turnkey solution

What we offer is not just software, but a complex solution including hardware which will provide complete and nonstop data collection. We also provide services for the design and construction of communication infrastructure in the workshops as well as connection to all models of production equipment

“AIS Conveyor 2.0» is a tool for shareholders and senior management that forms an objective picture of the current efficiency of production processes at the enterprise. Objective data are the basis for setting and monitoring the implementation of KPIs aimed at increasing production efficiency.

For production employees — this is a tool that will help you achieve new KPIs and improve the efficiency of production processes.

For production employees — this is a tool that will help you achieve new KPIs and improve the efficiency of production processes.

Customization according to your needs

Individual modification according to the company’s confirmed requirements of financial, management and production accounting systems. Integration to the existing informational systems.

Confidentiality

GlassTech LLC is an independent developer and owner of the solution. The shareholders of the company are individual persons and key members of the project team.

“AIS Conveyor 2.0» does not have access to the company's accounting data, but only provides the ability to automatically request and receive production data through standard protocols.

“AIS Conveyor 2.0» does not have access to the company's accounting data, but only provides the ability to automatically request and receive production data through standard protocols.

Systematic approach

"AIS Conveyor 2.0" combines autonomously controlled sectors of the conveyor production into a unified information system without replacing of the existing equipment and its process control systems, supplementing their functionality.

“AIS Conveyor 2.0” Advantages

Comparison of industry solutions — specialized MES systems for the container glass industry

Integration into the equipment system of all types and manufacturers starting from the composite workshop to the packaging of finished products

Our engineers will set up data reading and integrate absolutely any fleet of production equipment into a single system

Functional and technological

AIS Conveyor 2.0

Automatic calculation of production effectiveness indicators from cuts to packaging

Eliminates the human factor

Unit for the gob weight control

Specialized hardware part of the system which provides complete and continuous data collection from all production sections

Patented communication blocks allow to provide data collection with uptime of 99.9% at a new technological level

Turnkey digitalization in a single window form: design and installation of network infrastructure in workshops, deployment and configuration of the software part, integration with existing financial and management accounting systems

An integrated approach will significantly save time and money

Service characteristics

24/7 technical support

Key Characteristics

Other MES systems for the container glass industry

Analytical report on the work of the IS machine

It will show opportunities to increase the effective operation time of the IS machine

Optimal planning unit

Increase overall factory productivity through smart scheduling using productiveness statistics for each range of items on each particular line

Messages about target events: stop of the IS machine, stop of the section, exceeding the critical threshold of defects on the inspection machine, decrease in the level of glass melt in the furnace, etc.

The messaging system has flexible settings and allows you to implement any scenario according to your technical requirements

Parameters and operating modes database of technological equipment at each moment of time: IS machine cyclograms, IS machine section angle settings, furnace operation parameters, etc.

It will help to create optimal flow charts of equipment operation

Unit for mold sets accounting, control of operating time and lubrication of molds

Unit for pallet movement and shipment control

Connection of the hot and cold sections of the conveyor with measuring the workers reaction time

Reduce the time of defected product production. Find out how much time it takes from the occurrence of a problem to its solution

Without the measurement of response time

partly

How the productiveness of your factory will increase

after implementation of the “AIS Conveyor 2.0”

or

Increasing of productiveness

Additional profit by year

“When you can measure what you are speaking about — you know something about it. If you cannot measure it, you cannot improve it”

William Thomson, 1st Baron Kelvin 1824 — 1907

1st STEP

Inspection of workshops. Collection of the documentation for equipment and automated production control systems software with further analysis. Preparation of the report for the customer's confirmation.

~ 2 months

Implementation of the solution

6-10 months

2nd STEP

Development of an implementation project: schemes for laying communication lines, locations of communication blocks installation, development of modules for reading data from the APCS software

~ 3 months

3rd STEP

Laying of communication lines, installation of communication blocks and sensors, connection to the APCS software, installation and configuration of the software part, setting up a monitoring system for data collection and communication blocks operation, preparation of as-built documentation

~ 3 months

4th STEP

Commissioning works, putting the system into operation

~ 2 months

Contact Us

Learn more about "AIS Conveyor 2.0"

and about the possibility of its implementation in your factory

and about the possibility of its implementation in your factory

+91 99308 88110

Specialized technology platform for hollow glass factories

Contacts

Shamvik Glasstech

Corporate Office: 1513/1514,

Maker Chambers-V, 15th Floor,

Nariman Point, Mumbai -400021,

INDIA.

Corporate Office: 1513/1514,

Maker Chambers-V, 15th Floor,

Nariman Point, Mumbai -400021,

INDIA.